What is new in V4?

- More connectors and analog channels:

- 2 thermocouple inputs (in the front),

- 4 analog inputs (at rear),

- 2 counter inputs (available under request)

- 2 servo outputs (available under request)

- additional engine rpm input (0 to 5 volt), suitable to be connected to ECU output or inductive clamp adaptor.

What is new in V3 and 3b?

- Enhanced engine RPM input circuit. Hi sensibility for traditional

ignition and new ignitions (on-spark coils). Noise protection. click here for info about rpm reading

- 2 General purpose analog inputs 0-5v, suitable for lambda probe

Powerful and easy to use

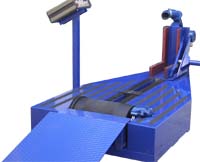

SmartPower SP-1 is a package that consists on:

SP-1 data acquisition unit (V4), with 8 input channels:

roller speed input

engine rpm input click here for info about rpm reading

2 thermocouple type K input (upto 1000ºC)

4 general analog inputs

2 counter inputs (available under request)

2 servo outputs (available under request)

And sensors:

Hall Effect active sensor to measure roller rpm

capacitive pickup to measure engine rpm

installation cables and SportDyno software

|

Connection is done by using PC serial port, this makes very easy to

connect this unit to any computer.

NOTE: There are new laptopts without serial port, but a RS232-USB

adaptor can be used to connect SP1 on this PCs. This adaptor creates a

virtual COM port that can be selected on the program to work with the unit as usual.

Theorically any RS232-USB adaptor will work with this device,

requeriments are 115,200 baud transfer. We can supply a well-tested

adaptor if you can not find a suitable one.

The equipment is completed with a modern Software

for Windows, very powerful and easy to use. It allows to work

simultaneously with several tests.

Specifications

Power supply: 220V 50Hz/60Hz (Europe) or 115 volt

50Hz/60Hz (USA) (please specify when doing your order)

Data transfer: 115200 baud RS232C (DB9 Conn)

(There is available a RS232-USB adaptor)

Roller rpm input connector (CN2)

- Type of sensor: Hall Effect active sensor (doesn't need external magnets)

- Type of input: logical Level (active at high level)

- Maximum frequency: 15 KHz (6,000 rpm with 150 teeth)

- Maximum cable length: 6m

- Run/Stop input SWITCH

Engine rpm input: capacitive type (reads high voltage pulses on ignition cables)

Display: LCD 16x2 Characters.

Installation and Connections V4

Installation and Connections V3

Dynamometer Intallation V4:

CN1-additional engine RPM input, 0 to 5 volt. Suitable for ECU output, or external adaptors.

CN2-Roller Speed Sensor (Hall Effect), and Switch input

CN3-Load Cell, not available at SP1

CN4-Digital Counters and Servo outputs, available in next version 4b

CN5-Analog connector, Analog channels 1 and 3 (J and L), from 0 to 5 volt, suitable for Wideband Oxigen Sensor

CN6-Analog connector, Analog channels 2 and 4 (K and M), from 0 to 5 volt, suitable for Wideband Oxigen Sensor

Dynamometer Intallation V3:

CN1- general purpose input. (lambda probe)

At CN1 connector are available two analog channels (input from 0 to 5volt)

that can be used to connect a lambda probe such as Bosch LSM11.

CN2- pickup connection.

pick-up should be mount close the geared tooth. Maximum frequency

of teeth should not be greather than 15 Khz, so the gear teeth will be max of 150 teeth

(for 6,000 rpm of roller).

Start/Stop Button on CN2 to control the dynamometer operation.

Applications:

| RC Model engine dynamometer. |

|

Last modified SEP/28/2009

|